We solve the major challenge of robotic hanging and collecting of mixed parts in KTL coating processes.

As Ümisy Machine and Robotics Technologies, we are solving one of the biggest challenges in cathodic dip coating (KTL) facilities!

The robotic hanging and collecting of mixed parts — which has long caused time loss, high costs and quality risks in coating processes — is now performed fully automatically.

The key problems faced until today

• Manual collection of mixed parts ➜ high labor cost

• Incorrect hanging ➜ repeated processing & rework

• Surface scratches / quality loss due to contact

• Long masking times

• Slow production flow & loss of traceability

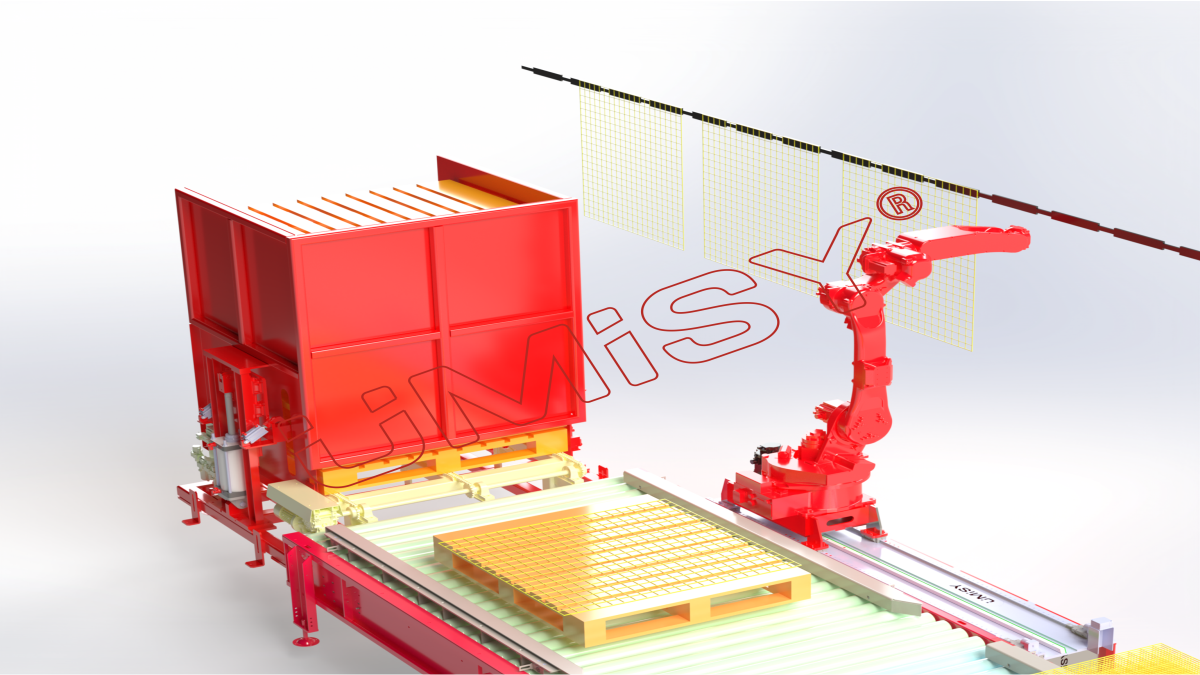

Ümisy’s solution: Robotic Hanging & Collecting Processes

With our next-generation system:

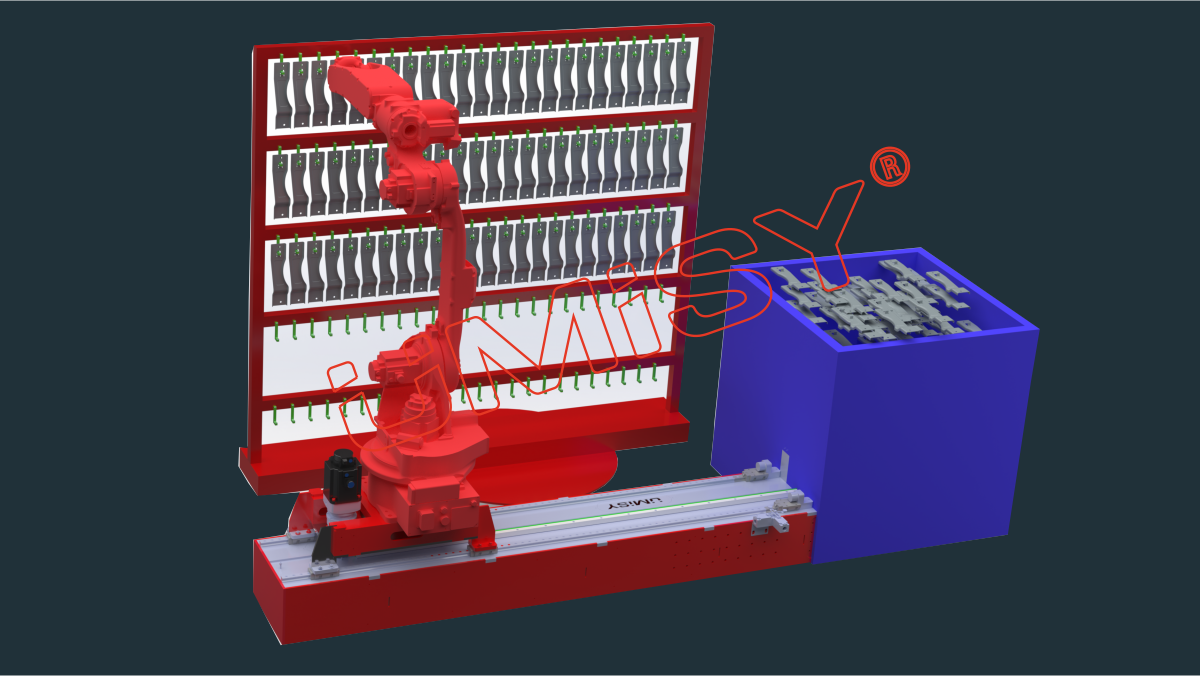

🔹 Mixed parts inside uncoated baskets are detected by a camera

🔹 The robot automatically picks parts according to the correct orientation

🔹 Hanging takes place based on recipes — 100% traceable

🔹 After coating, the robot collects the parts again and performs surface quality inspection

The impact

✔ Dramatic reduction in labor costs

✔ Fast and uninterrupted production

✔ Minimal surface and masking errors

✔ Fully digital traceability of part distribution, hanger position and quality reports

KTL facilities are no longer just coating lines —

They are transforming into smart production stations that think, analyze, control and optimize.