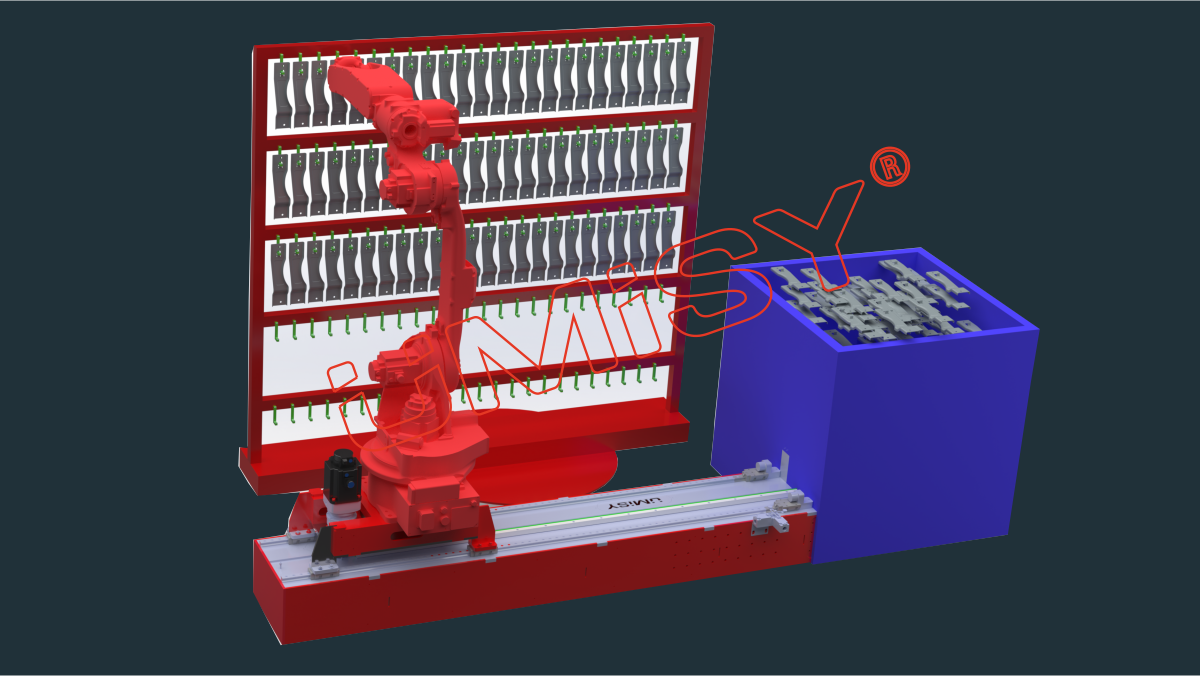

100% Robotic Solution for Hanging and Unhanging Processes

We now provide a fully robotic solution for hanging and unhanging processes.

As a result of our R&D efforts, we have transformed one of the biggest challenges in coating and painting lines — hanging, unloading, and quality control processes — into a fully automated system using robotics and machine vision.

🔍 How Does It Work?

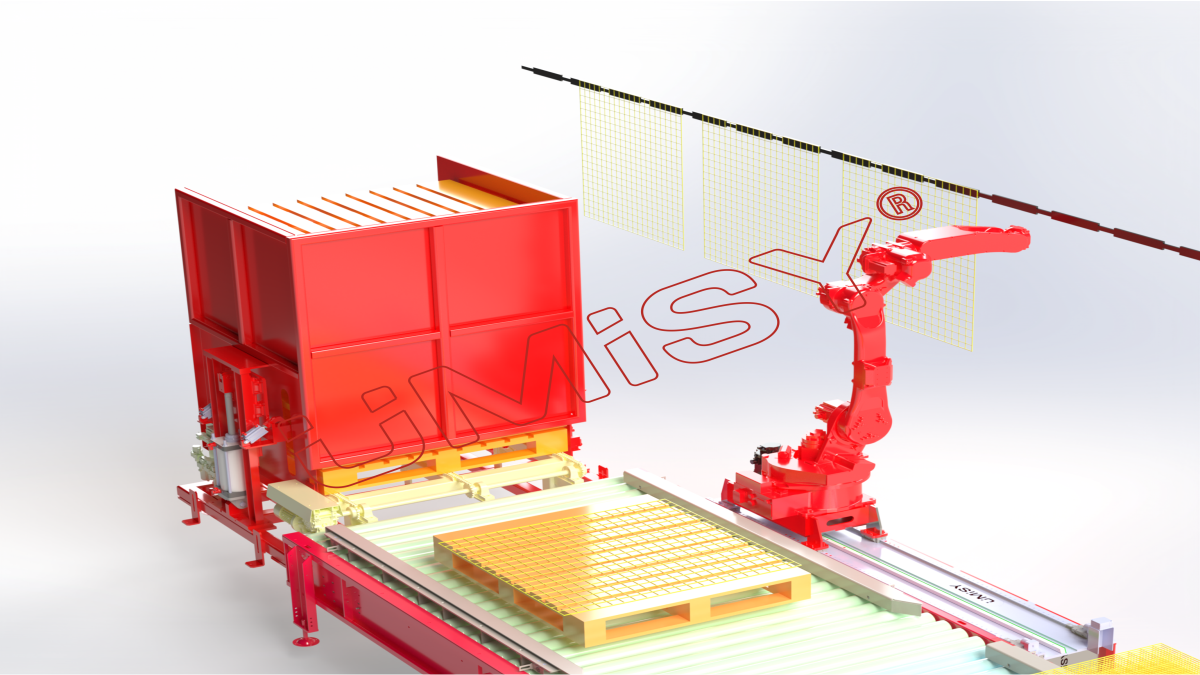

• Parts arriving on pallets are detected via camera-based position recognition and picked by the robot gripper.

• Moving hangers are tracked using a motion tracking card, monitoring line speed and distance in real time.

• The robot synchronizes with the hanger system on a slider axis, completes the hanging operation, and immediately proceeds to pick the next part.

🧩 Applicable Parts

✔ Automotive components

✔ Molded parts

✔ Defense and aerospace industry parts

✔ Fences and panels

✔ Square profiles and round bars

✔ All parts suitable for hanging and unhanging operations

🎯 Integrated Quality Control Systems

• Surface inspection

• Roughness (Rz) measurement

• Paint or chemical drip detection

• Corrosion inspection

• Product geometry recognition

➡️ All results are traceable and reportable

🎨 Designed for Coating and Painting Lines

The system is specifically designed for KTL (E-coating) and painting applications.

🤖 Ümisy – Making Your Processes Smarter with Robotics