100% Robotic Solution for Hanging and Unhanging Processes

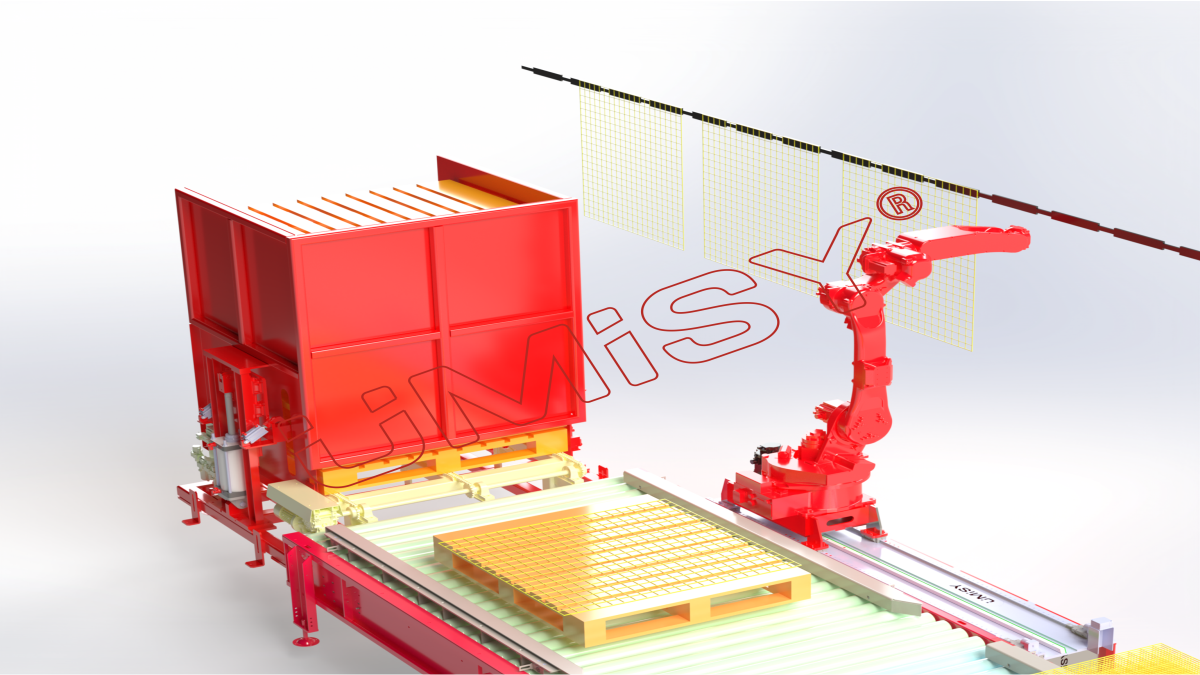

We now provide a fully robotic solution for hanging and unhanging processes.

As a result of our R&D efforts, we have transformed one of the biggest challenges in coating and painting lines — hanging, unloading, and quality control processes — into a fully automated system using robotics and machine vision.

🔍 How Does It Work?

• Parts arriving on pallets are detected via camera-based position recognition and picked by the robot gripper.

• Moving hangers are tracked using a motion tracking card, monitoring line speed and distance in real time.

• The robot synchronizes with the hanger system on a slider axis, completes the hanging operation, and immediately proceeds to pick the next part.

🧩 Applicable Parts

✔ Automotive components

✔ Molded parts

✔ Defense and aerospace industry parts

✔ Fences and panels

✔ Square profiles and round bars

✔ All parts suitable for hanging and unhanging operations

🎯 Integrated Quality Control Systems

• Surface inspection

• Roughness (Rz) measurement

• Paint or chemical drip detection

• Corrosion inspection

• Product geometry recognition

➡️ All results are traceable and reportable

🎨 Designed for Coating and Painting Lines

The system is specifically designed for KTL (E-coating) and painting applications.

🤖 Ümisy – Making Your Processes Smarter with Robotics

Read More...

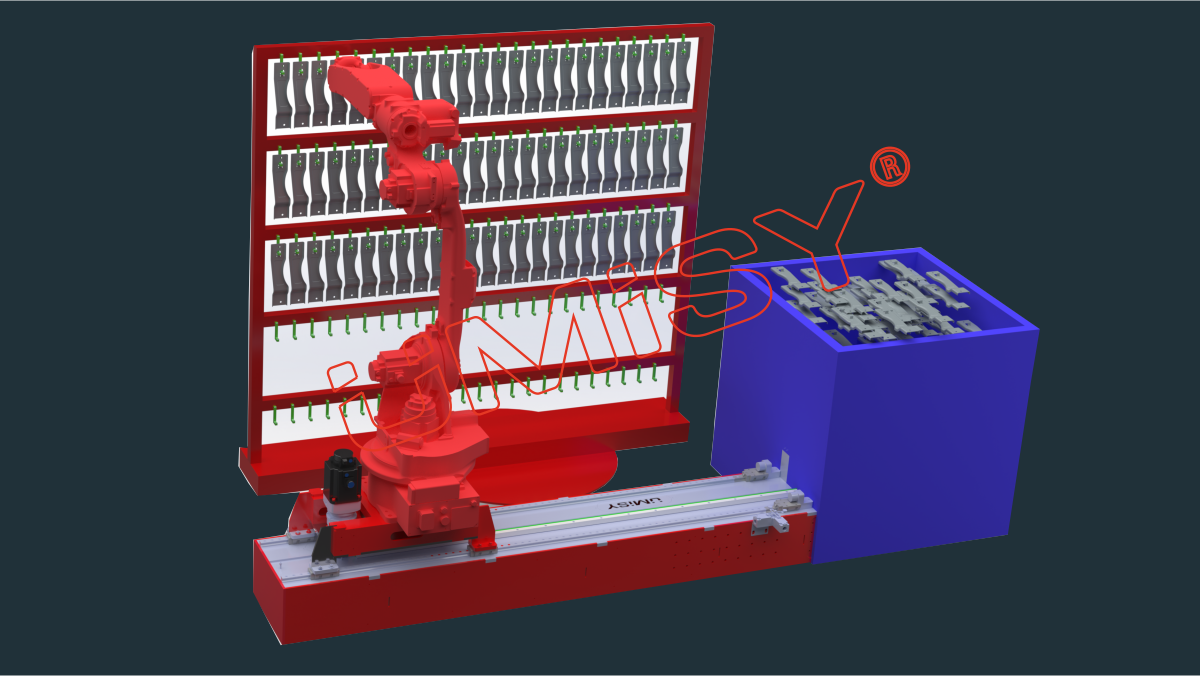

We solve the major challenge of robotic hanging and collecting of mixed parts in KTL coating processes.

As Ümisy Machine and Robotics Technologies, we are solving one of the biggest challenges in cathodic dip coating (KTL) facilities! The robotic hanging and collecting of mixed parts — which has long ca...

Read More...

Ümisy Implements SRCI Integration with Siemens and Yaskawa!

🚀 Ümisy continues to achieve firsts in Turkey!We are proud to announce that we are the first company in Turkey to launch the Siemens Robot Library Project. With our vision of not only following innov...

Read More...

Your cathodic dip coating (KTL) facility is no longer just coating… It is transforming into a smart production station that thinks, analyzes, measures, optimizes, and operates data-driven.

🔹 1️⃣ KTL Bath Measurements & Automatic Chemical DosingContinuous analysis of bath chemical parameters ensures automatic dosing, keeping both coating quality and chemical consumption fully under...

Read More...

We continue to implement robotic solutions in cathodic dip coating (KTL) facilities…

KTL Bath Measurements & Automatic Chemical DosingUp to 80% Savings in Part Masking CostsPrevention of Stains and Labor Loss with Robotic Air BlowingMixed Part Hanging & Pick-from-Original insi...

Read More...

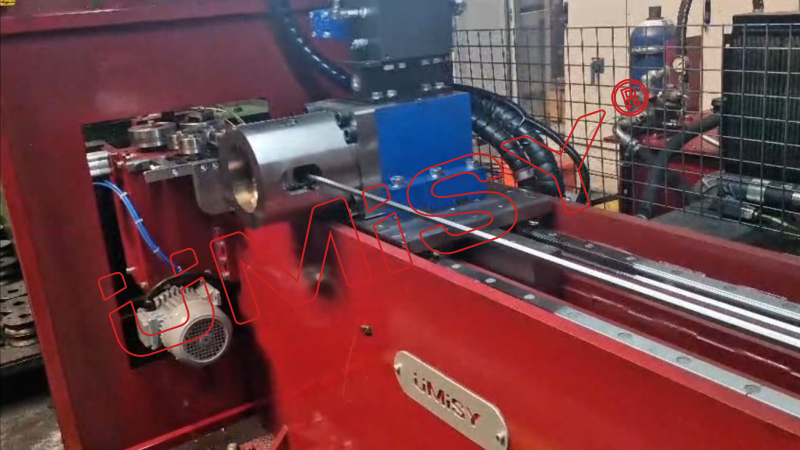

Hydraulic Impact Shear

The hydraulic impact shear cuts the material during continuous operation using two shear bushings.The electric servo drive enables precise speed control of the shear carriage. The high cutting speed a...

Read More...

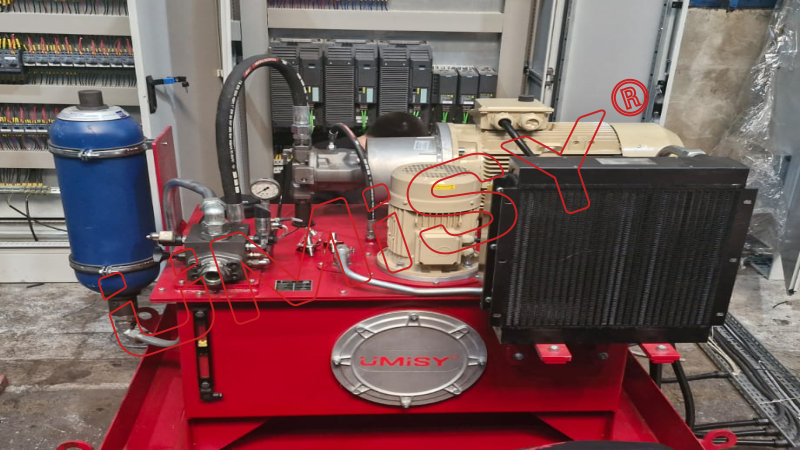

Our hydraulic unit equipped with Bosch Rexroth technology is now ready for the customer journey…

As Ümisy Machine and Robotics Technologies, we add engineering excellence to deliver seamless systems built with first-class equipment.With our custom hydraulic systems and cylinder (piston) manufactu...

Read More...